An Industry Breakthrough: Safe, Scalable, Low-Cost Prelithiation

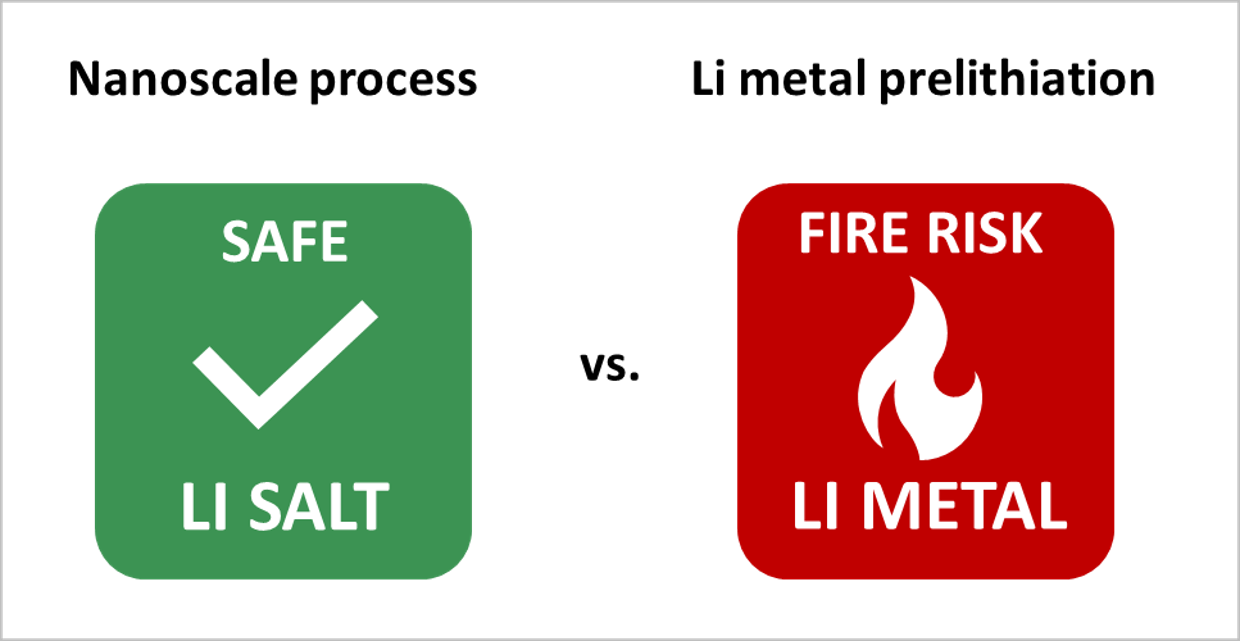

A safe process using salt rather than metal

Prelithiation has always been desired, but previous approaches using lithium metal could not be commercialized readily due to safety and cost issues.

Nanoscale’s Process

Safe salt: Electrochemical process uses a safe, stable lithium salt instead of metal

Safer manufacturing: No lithium metal or flammable solvents are used, eliminating key fire risks

Safer cells: No lithium metal is in cells, eliminating tendency to form dendrites

A scalable process that operates roll-to-roll

Single pass design: simultaneous prelithiation across both sides to maximum anode width of 700mm

For gigafactories: modular design offering scalable production, planned for continuous 7×24 operation

Precisely controllable: patented electrochemical process offers precise dosage control facilitating optimal and reliable cell performance

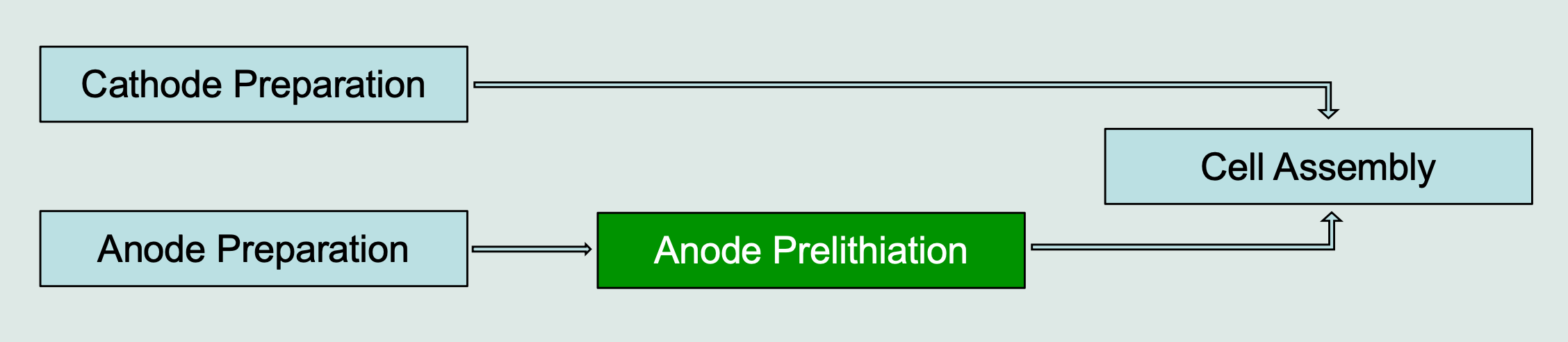

Easy to integrate: existing anode coating equipment is unchanged. Prelithiation equipment is placed after electrode calendering and may feed directly into next assembly step (e.g., stamping)

An inherently low-cost process that reduces your cell cost/kWh

Less expensive/kWh: Prelithiated cell energy increase is greater than the process cost

Low-cost salt: less expensive than Li metal

Non-flammable solvent: keeps processing costs low

Self-contained prelithiation equipment: doesn’t occupy dry room space

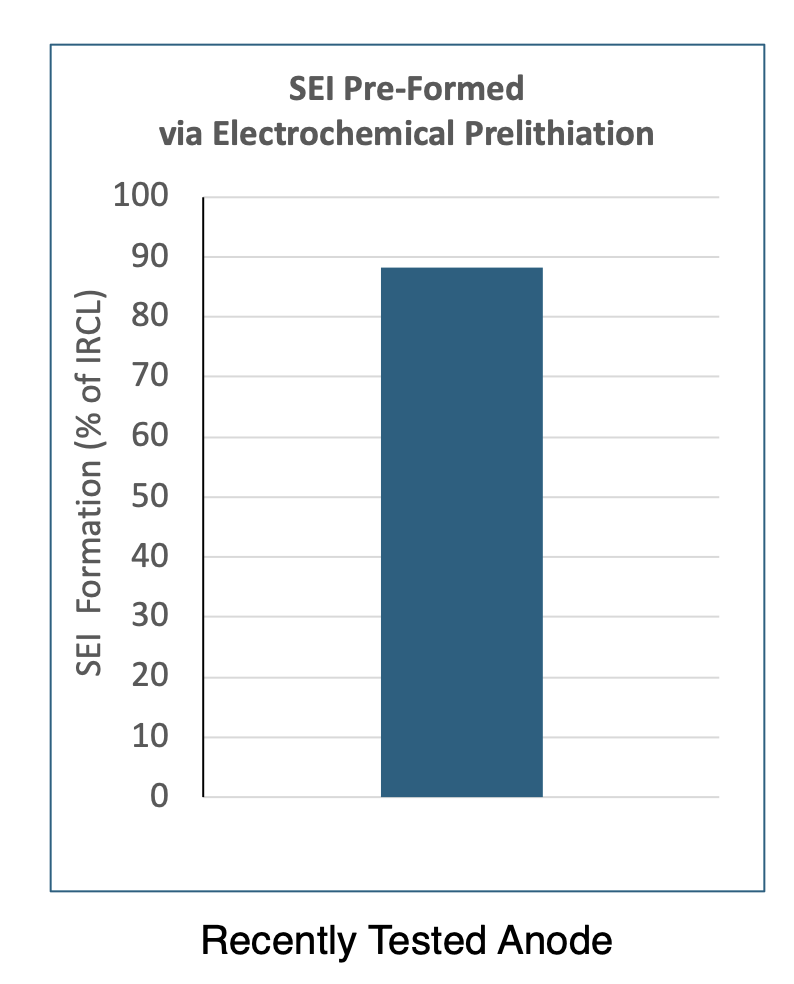

Reduced formation: up to 90% of SEI already formed during prelithiation

A compatible process

- Prelithiation can be added easily. All your existing anode and cathode coating equipment are unchanged.

- Just prelithiate coated and calendered anode electrodes, and then assemble cells under normal dry room conditions.